Mining companies can't rely on ageing systems to support the business activities of the future. To remain competitive, they need to transform, create new operating and business models, and foster and embed a strong digital culture.

In an ordinary open-pit or underground mining operation, the weekly production schedule received by short-term planners is based on the medium-term production plan. This schedule is then divided into days, shifts and hours for detailed planning and scheduling of resources.

Although this may seem simple, but the coordination between the weekly production schedule and production execution is one of the top challenges faced in modern mines, which can impact operational efficiency and raise costs.

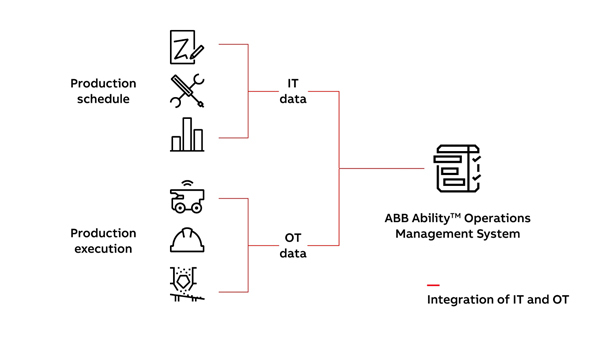

Enabling true integration of Operational Technology (OT) and Information Technology (IT) can close the gap between production scheduling and execution, enabling schedulers to perform predictive production scheduling, automated execution and react to a disturbance in seconds.

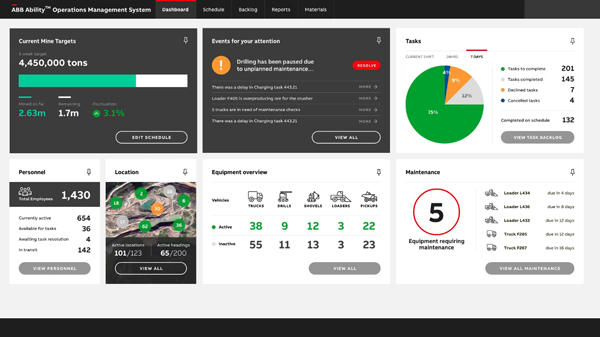

The ABB Ability™ Operations Management System for mining integrates two tools into the same digital platform: Short Interval Control and Closed Loop Scheduler. When high-level planning is combined with low-level control, the mine operator acts as a dispatcher, optimising resource usage in real-time and following the production plan more effectively.

ABB Australia's mining lead Richard Marsh explains: "The ABB Ability Operations Management System enables miners to get greater visibility and control of their mining operations by integrating the systems used by mining schedulers, operators and supervisors. This improves the performance of personnel, equipment and activities across your mining operation."

Short Interval Control allows mine operators to monitor and review operational plans and performance based on targets, metrics and KPIs. Variances can be analysed and mitigated in real-time during a shift for immediate corrective action or they may be reviewed and reported at the end of shift.

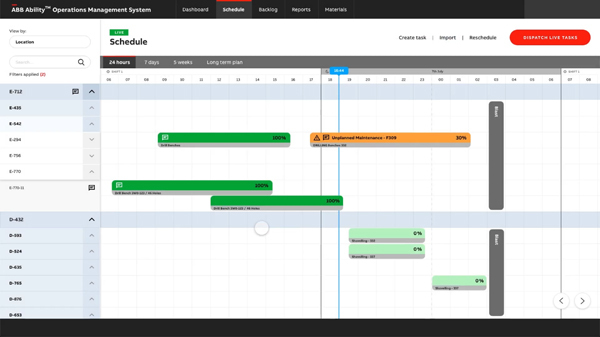

The Closed Loop Scheduler combines high-level planning with low-level control. The short-term planner achieves new levels of production scheduling efficiency, and can maximise production throughout blast cycles, haulage, crushing, ore processing and transport. The mine operator then acts as a dispatcher, optimising resource usage in real-time and following the production plan more effectively.

The ABB Ability Operations Management System is an intuitive system that can be seen by the planners and operators at the same time, creating better visibility of what is happening in real-time. The team can get notifications in real-time, predict and automate new schedules.

The unique ABB Ability Operations Management System approach effectively closes the loop between planned and real-life operation, enabling:

- mines to reduce variability and have improved responsiveness to unplanned events

- equipment availability to be maximised by moving from a reactive to a predictive maintenance model

- operational awareness for all personnel

- mines to act as ore factories, moving toward a continuous and large-scale mine-to-port operation

- ore inventory to be tracked and controlled, allowing for maximum flow and optimal grade.

Watch this short video now on how ABB Ability Operations Management System can improve your mine operations or read the case study of how it improved the Boliden mine in Sweden.

ABB is a market leader in mine digitalisation, mine automation, electrification and mine hoists. Companies of all sizes around the globe trust ABB to be their digital transformation partner. For more stories on how ABB shifts the centre of gravity towards mine optimisation and digitalisation, visit ABB's future of mining site.