It is an unfortunate fact of life that while working in our industry we are exposed to hazards on a daily basis. It is vital companies make every effort to provide a safe working environment and provide effective employee training to minimise risks while working.

Capital Drilling continues to implement safety iniatives across its operations with a recently commissioned remote blast hole rig at the Sukari Gold Mine in Egypt. Additionally, it employs the IRIS safety and surveillance system at select sites.

Improving effectiveness of employee safety training

Effective employee training assists in prevention of workplace injury and accidents. To further increase effectiveness, training programs that incorporate video will significantly improve employee retention of the training content.

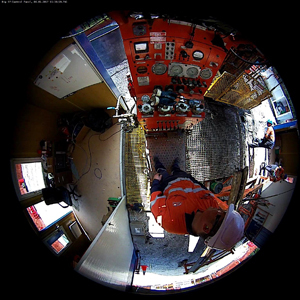

The IRIS health and safety surveillance system strategically mounts a number of cameras across a drill site, including on the drill rig, to provide a complete view of the work site. It records footage from all angles and stores it on a server that can be accessed remotely if required.

The footage allows for the use of live or recorded footage to be used in employee inductions and health and safety training programs.

This real site-based footage shows employees safe work procedures in their operating environment before they even step onto site. It also allows for demonstration of how to safely complete a task to avoid injury and comply with health and safety procedure requirements in the employee's actual drilling environment.

The system also provides the capability for supervisors to monitor rig activity in real time and intervene immediately to prevent behavioural based workplace injuries if required.

If an incident does occur, the IRIS system's recorded footage provides investigators with a complete view of what actually happened. This dramatically reduces investigation time and therefore associated shut-downs.

The system has further benefits of providing additional safety and security features including helmet tracking, crowd counting, facial recognition and geo-fencing - alerts can be sent directly to mobile devices if a breach has occurred for immediate action.

Improving safety on the bench

Capital Drilling has recently commissioned its first remotely operated Blast Hole rig at Centamin's Sukari project in Egypt. Combining a Remote Drill module supported by a self-contained truck-mounted Drill Control module, it allows safe and productive drilling in high risk work areas, where the operator is positioned a safe distance away from the rig without impacting operational efficiency or quality.

Capital Drilling has an uncompromising commitment to the occupational health and safety of its employees and others where it works. These are part of a broad range of safety initiatives the company uses to keep employees safe and to constantly reduce their exposure to risk while performing their work. The company will continue to implement innovative approaches to improve safety across its operations.

For further information please visit our websites www.capdrill.com and www.iriscorp.net